Projection Welding

Customized solutions for projection welding

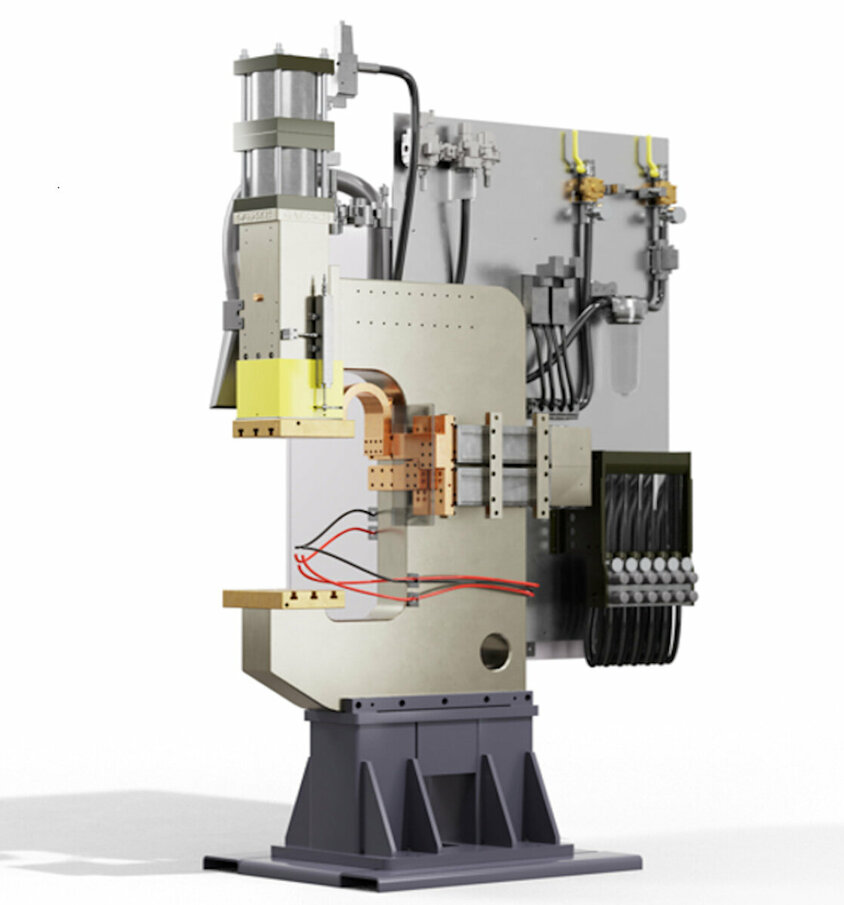

Projection welding machines are a critical component of modern manufacturing technology, and at Gatzsch Schweißtechnik GmbH, we offer you the optimal solution: Our G-Prime projection welding machines deliver the highest precision and reliability, designed to consistently ensure high-quality standards in projection welding, even under the most demanding conditions.

Many years of expertise and state-of-the-art technology: Projection welding at the highest level at Gatzsch Schweißtechnik

At Gatzsch Schweißtechnik, we can look back on many years of expertise in the field of resistance projection welding. We have been successfully using this high-precision process for many years to offer our customers from various industries optimum joining solutions. By continuously investing in state-of-the-art technologies and constantly developing our production processes, we are able to ensure consistently high quality. Our experienced engineers work hand in hand to develop customized solutions that are precisely tailored to the specific requirements of each project.

Efficient process monitoring during projection welding: Quality assurance in real time

Process monitoring in projection welding is crucial to ensure the consistently high quality of welded joints. By using modern monitoring systems, parameters such as amperage, welding time, and electrode force can be controlled and optimized in real time. This minimizes the risk of errors, such as insufficient welding or material distortion. In addition, process monitoring enables complete documentation, which is essential not only for quality control but also for the traceability and optimization of future welding processes. This ensures that every weld seam meets the highest standards.

Our product lines

G-Prime

Stand-Alone

This variant is the ideal choice for companies that require independent and flexible welding solutions. With its compact design and comprehensive equipment, it offers everything necessary for an efficient and smooth production process.

G-Prime

Integrator

Perfect for seamless integration into existing production lines. The G-Prime Integrator combines state-of-the-art technology with simple integration into your existing systems to optimize your processes.

G-Prime

Integrator Light

Developed for smaller applications, this version offers a cost-effective solution that still ensures all the essential functions for reliable projection welding.

Experience precision in projection welding - request your individual solution now!

Take advantage of the outstanding technology of our projection welding machines and optimize your production processes. Contact us now and let our experts advise you.

Projection welding technology and equipment

The G-Prime projection welding systems from Gatzsch Schweißtechnik can be fully equipped to meet even the highest requirements:

- Protective housing and light curtain for maximum safety at the workplace

- Sequence control with visualization for precise monitoring of the welding process

- Proportional pressure control and sink path monitoring for precise and repeatable welding results

- Interchangeable projection welding tools for maximum flexibility in production

- Installation plate with media supply including cooling water pre-filter, cooling water distribution and low cooling water switch to ensure reliable and efficient cooling of the welding systems

Electrode force in projection welding

The electrode can be pneumatic, servo-pneumatic or electric, making our machines extremely versatile. Depending on requirements, the electrode force varies between 14, 24, 36 and 60 kN.

Rated power in projection welding

Different nominal outputs are available, which are realized in both single and multi-pulse technology, in order to be precisely tailored to your specific requirements.

| AC (kVA at 50 % ED) | MF (kVA at 20 % ED) | KE (KJ) |

| 180 | 250 | 13 |

| 250 | 380 | 18 |

| 500 | 500 | 36 |

| 1.000 |

Innovative projection welding solutions for your production

The G-Speed repositioning unit adapts precisely, even with rapid increases in welding current and short dips in electrode force. The secondary window, made from a ferrum-free aluminum C-frame, ensures exceptional rigidity and exact parallelism of the pole plates. Thanks to the special material, the ferrum-free design, and the minimum number of contact resistances, the unit offers low electrical resistance and enables an extremely high welding current rise speed.

What is projection welding?

Delve deep into the theory of projection welding and understand why this process is essential for modern metal processing. Discover how this welding process works, what the technological requirements are, and what different types of projection welding exist. Click here to explore the theoretical basics and technical details of projection welding and deepen your knowledge.